| Home | Prev | Next |

Last September 16, 2015, 30 Philippine printers visited Komori Corporation’s ultra-modern production plant in Tsukuba. We were met at the factory by Mr. Rey Alviar, President of Grapteck, Inc, Komori’s Philippine distributor, and Mr. Joe Erasquin.

This 60,000 square meter site is the world’s largest press manufacturing facility, integrating manufacturing, assembly, testing, research and development, demonstration and training.

After a video presentation about the history of the Company, its management philosophy, its facilities and its high-quality products, we were guided around the plant facilities.

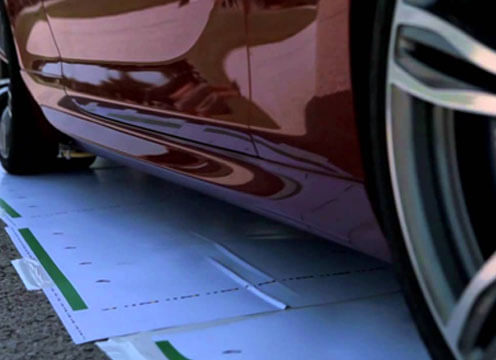

We were shown the presses in various stages of production, from the four colour LA37 conventional presses to the full-spec six colour, carton packaging press, GL40 with coating, eight colour GX40RP 4/4 reverse printing dedicated double-sided press with H-UV, their 16-page System 38S web press, all the way to the specialized currency presses.

It was extremely impressive how the factory was highly automated and even though they were busy with their daily production targets, remained impeccably clean, tidy and so organized. We witnessed machinery precision engineering at its absolute finest.

We were also shown around the Komori Graphic Technology Center (KGC) whose role is to promote the realization of “a company that provides Kando to its customers.”

The four functions of KGC are:

- To provide customers the opportunity to evaluate Komori systems through tests and demonstrations – The Demonstration Center

- To educate customers about printing technology, both hardware and software – The Printing College & DoNet

- To train production and service experts to provide technical support worldwide – The Technical Training Center and

- To perform research on printing technology, including collaborations with universities and manufacturers – The Printing R&D Center

These functions within the Komori Graphic Technology Center – integrated into the state-of-the-art design, development and manufacturing of the Tsukuba Plant, are daily raising the level of skills, know-how and printing software that are indispensable to getting the most out of Komori’s industry-leading press hardware.

In IGAS, the Komori stand featured their hottest, full-spec machines flexing their muscles while demonstrating state-of-the-art color management solutions to large, awed crowds. They have the very finest offset lithography presses, they have digital toner, they have inkjet, and they have nanography. The display of the Impremia IS29 and their still-under-wraps Komori-Landa nanographic press to be debuted at Drupa, shows that Komori is facing the future bristling with a full arsenal.

That, indeed, is Kando – Exceeding expectations.